Long-Screened Test Well Profiling

Introduction

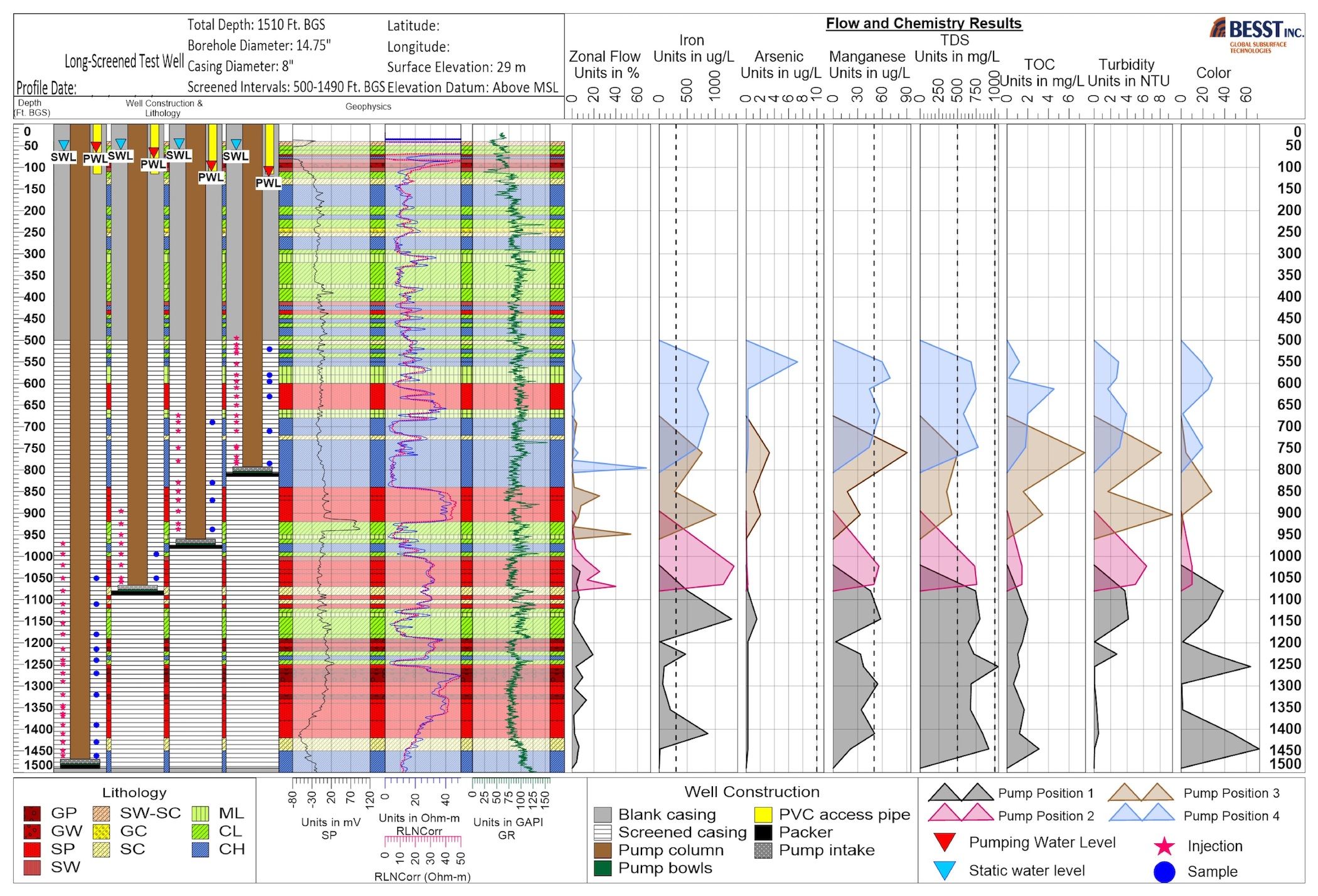

BESST Inc. has integrated the practice of test well investigations with the precision and granularity of BESST’s proprietary dynamic flow tracer and chemistry profiling to confidently inform development of production wells. A dynamic, steady state flow and chemistry profile is employed in a long-screened test well with a custom injection and sampling plan to best characterize the subsurface environment in tandem with lithologic and geophysical data. The data gathered and analyzed from the long-screened test well aids in determining the most viable and effective construction for a proposed production well; including recommendations for screen and blank casing locations, pump depths, and pumping rates to develop a long lasting well.

Methods

The long-screened test well application begins with determining the right location for drilling or testing an existing well in the immediate area of a proposed production well. For example, an existing monitoring well with a long screen, usually exceeding 300 feet in continuous length, may take the place of drilling and developing a long-screened test well. Once the informed construction is underway, or the existing well is modified to testing standards, a team of scientists gathers the geologic data in the region and of the well to best advise the testing methods. The long-screened test well sampling typically delineates 15 zones along the length of the screen, but this may be adjusted based on the client’s needs. In most instances, an electric submersible pump is deployed to the bottom of the well to engage the entirety of the well screen. Once the well has been sufficiently pumped and developed, the Dynamic Flow Profile is conducted in a span typically lasting two full days. The flow data is used to mass balance the chemical influence of each zone within the well and at the wellhead, producing a flow and chemistry scenario that will be used in forming recommendations for the development of a production well based on the clients desired water yield and chemical allowances. During the long-screen test well profile, a pump and packer assembly may be used in isolating portions of screen to maximize engagement to smaller zones along the screened interval. This process has been used to ensure screen engagement and compare pump placement locations to the overall chemical yield of the well.

Results

The long-screened test well technology is proprietary and innovative in the groundwater community and has already provided clients with deep understandings and unprecedented foresight into their future well designs. Furthermore, this technology has been integrated into entire basin characterizations for a variety of basin planned use projects. The data gathered during this test has been used in conjunction with groundwater modeling to accurately identify constituent mass and water production potential in the subsurface. Pictured below include graphs and figures conceived from past long-screen test well projects.

50 Tiburon St, Suite 7

San Rafael, CA 94901

Office: (415) 453-2501

lemmens@besst-inc.com

(415) 453-2501 ext. 101

nheller@besst-inc.com

(415) 302-7354

mkoehler@besst-inc.com

(510) 414-9984

jtsumura@besst-inc.com

(626) 512-3715