Packer Feasibility Testing

Introduction

Packer feasibility tests (PFT) are a temporary well modification, utilizing a single or multiple packer system in conjunction with thorough well testing to inform permanent well modifications or new well designs. BESST Inc. has overseen dozens of successful well modifications proceeding packer feasibility tests.

Methods

The PFT begins with a comprehensive study, often including a dynamic or ambient flow and chemistry profile, of a well impacted with any combination of water quality or production issues. A packer feasibility test is recommended if it is deemed suitable for addressing conditions provided in the preliminary studies. Suitable conditions for a PFT typically include identifying a zone contributing a significant portion of a constituent of concern. The packer is set in correlation to the zone of concern, with also consideration of production requirements, other chemical impacts from the packer placement and efficiency of the pump. The packer system is designed by a team of experienced hydrogeologists in conjunction with the affiliated pump company to implement the construction. The construction and implementation of the packer system may be accompanied by various well rehabilitation efforts to maximize production potential and facilitate increased production in zones targeted for improved quality.

Following the successful completion of installing the packer and modification system into the well, various tests are performed to exact data on optimized pumping rates in the modified well to meet a balance of well efficiency, water quality, production potential, and pumping sustainability. This information is recorded over a regimented period to provide valuable insight into permanent modification construction and future well designs.

Results

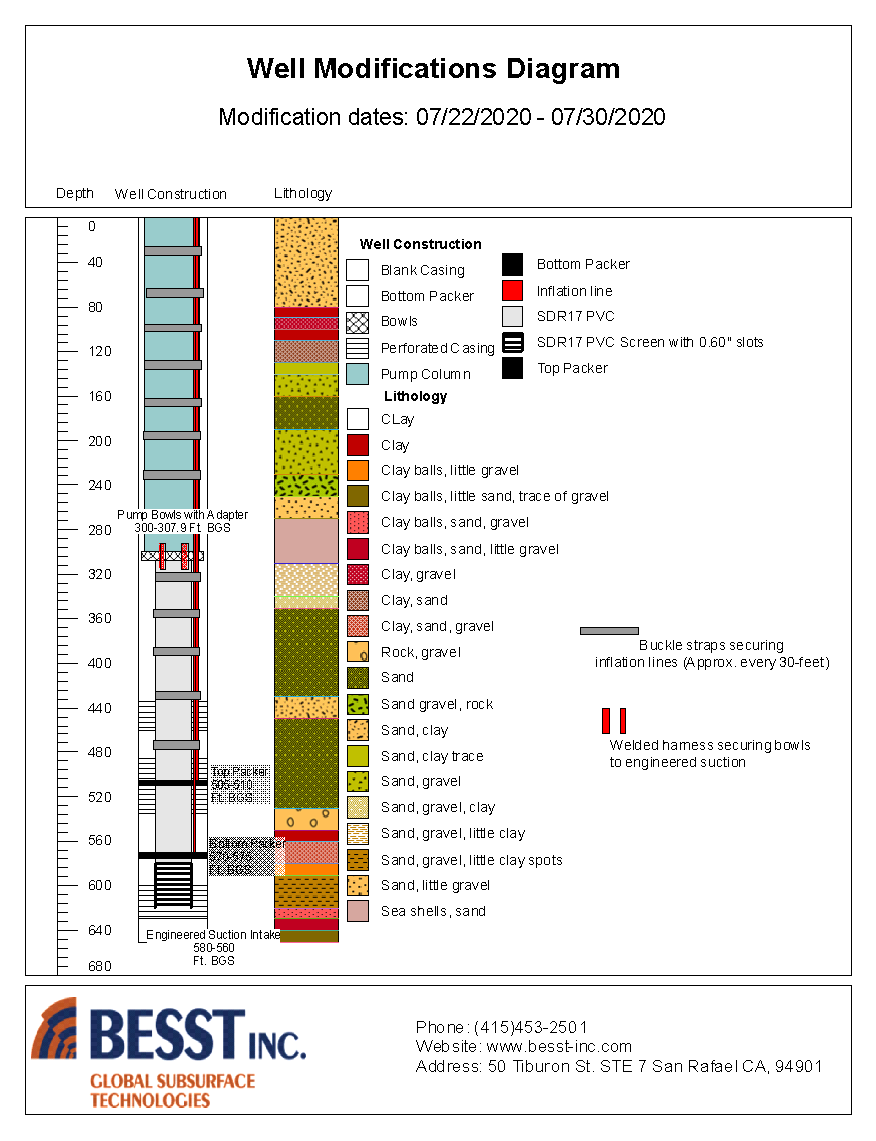

Successful applications of the packer feasibility test have provided numerous clients with confidence in well modifications. PFT modifications have saved millions of dollars for water purveyors through improvement of well water quality without the necessitation of installation and upkeep of water treatment systems. The following figures display a dual packer system installation diagram, as well as graphs displaying wellhead concentrations of contaminants after a packer installation.

Figure 1: Dual packer system to reduce wellhead hydrogen sulfide from zonal hot zones. The dual packer system was used to provide the client with multiple options to balance production and wellhead chemistry needs.

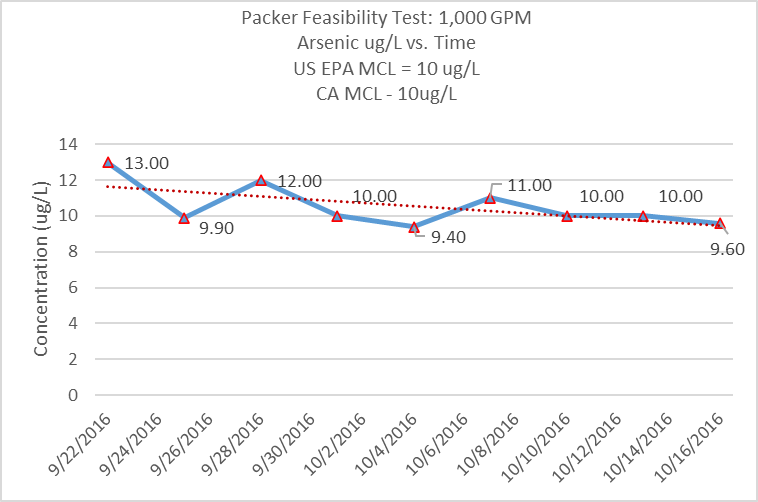

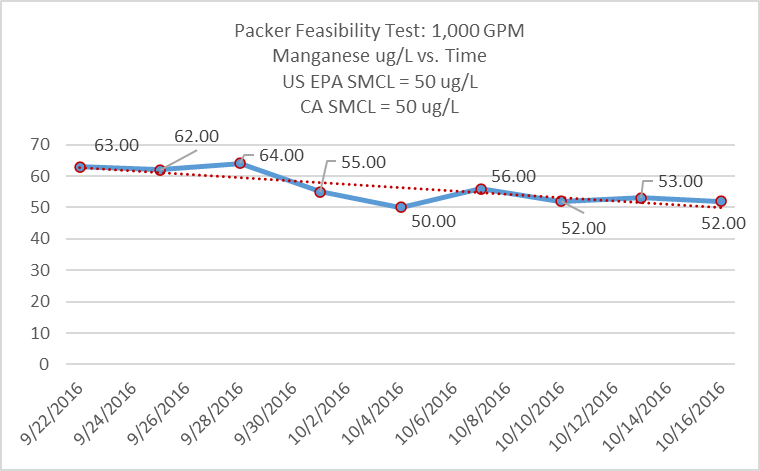

Figure 2: Arsenic, manganese and iron concentrations are tracked within the first few weeks of operating the well after the installation of a packer. The well was put back online after only a few months and now supplies its community with clean water.

50 Tiburon St, Suite 7

San Rafael, CA 94901

Office: (415) 453-2501

lemmens@besst-inc.com

(415) 453-2501 ext. 101

nheller@besst-inc.com

(415) 302-7354

mkoehler@besst-inc.com

(510) 414-9984

jtsumura@besst-inc.com

(626) 512-3715